What is a flameless regenerative thermal oxidizer ?

A flameless regenerative thermal oxidizer is a device that helps companies in various industry stands purify the air and reduce emissions within it. Functioning as an air purifier with a complex structure, a flameless regenerative thermal oxidizer is adapted for use in circumstances, which might pose a flammable risk. Read on to find out about the characteristics of a flameless regenerative thermal oxidizer.

- Reducing health risks.

Due to the purifying function, the flameless regenerative thermal oxidizer helps companies mitigate the adverse effects that emissions of VOC (volatile organic compounds) can cause. Health risks can be associated with certain carcinogenic threats and can also lead to photochemical reactions, according to recent international research. - Energy savings.

Even though the initial investment might be considerable, especially for smaller-scale plants, the device can lead to long-term energy savings. The actual benefits of thermal oxidizing processes can far outstretch the purifying effects mentioned above. - Heat recuperation.

Recuperating the heat, which is produced during the thermal process, is just one of the most obvious benefits of this process. Excess heat can be captured and reused in different ways, such as heating the sanitary water and the heating system.

Trust the regenerative thermal oxidizer manufacturers with experience and expertize

Many regenerative thermal oxidizer manufacturers claim to have mastered the technologies needed to be able to offer considerable energy savings and ecological benefits. Yet, not all producers can guarantee the respect of the strict ecological standards, which are considerably higher in the European union than they might be in other parts of the world.

Therefore, for the EU companies especially, or for the companies wishing to sell their products to the European market, the highest standards of production should be observed. This includes buying from those regenerative thermal oxidizer manufacturers that can satisfy the strict conditions.

Let us not forget that many of the VOC that are being processed can be found in several industrial processes of many industrial branches. This means that, potentially, many millions of European consumers are at the risk of being affected. These contaminants can be decomposed by using certain remedial processes, like oxidation and chemisorption. What are the advantages of trusting an established company with your order?

- High-level of knowledge and expertize.

By having been active in this demanding market for years, the regenerative thermal oxidizer manufacturers have been able to gather valuable production and research experience that can help them address the needs of the clients. Only the top-quality materials and up-to-date technologies can meet the demands of today’s highly specialized and evolving industries. - After-sales service.

Not only the production methods, but also the installation and after sales services are a benefit that a manufacturer with a solid background can guarantee. A network of technicians and engineers, topped by administrators that keep track of the customers’ files, means that any possible issue on the ground will be dealt with swiftly and within the shortest deadlines. - Tradition and recognition.

There is a reason why only a few brands have gained recognition in this demanding field of activity. Considering the highly competitive, yet rewarding surroundings, only the manufacturers that can guarantee the highest quality level, together with a state-of-the-art customer service, can count on the customers’ loyalty for long periods of time.

Find the Regenerative Thermal Oxidation Equipment that answers to your needs

Finding the Regenerative Thermal Oxidation Equipment that meets the needs of your industry and your company’s size can be challenging. This is another reason why we recommend that you consult an expert before making the choice.

The mistakes associated with the wrong decisions as far as Regenerative Thermal Oxidation Equipment goes, can be measured in several thousands of euros and span over many years. What are the factors that you should bear in mind when choosing the right model?

When it comes to choosing the right size, it is worth noting that a device is sized based on the capacity of the airflow of all sources of emissions combined. When considering the device’s efficiency, please note that it can reach up to 97% of thermal and 99% of destruction efficiency.

How does a regenerative thermal oxidizer work ?

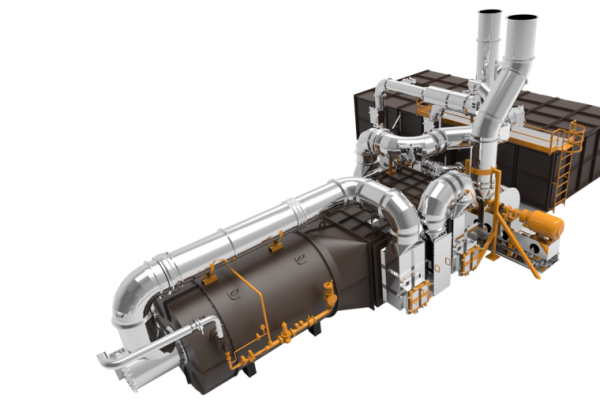

In the end, it might be worth remembering that the components and the processes determine how does a regenerative thermal oxidizer work. While the theory sounds relatively straightforward, it is the details of the execution that can make or break the efficiency of a device. Its main parts are the following: the combustion chamber and air blowers, as well as waste burners.

The process can be remotely controlled and programmed, thus allowing for the greatest possible oversight and maximum use. Contact the sales team and get an offer, together with the opinion from our experts.